DrM can supply stand-alone candle filters or complete, skidded turnkey packages. All of our filters are custom-designed to meet the needs of each application. Unique Options are available above the minimum supply scope to optimize performance, operation efficiencies and flexibility. The following is a description of some of these Options:

Overfill Protection Device

Filtration involves separation of two phases while one phase passes through a media and the other is retained. The retained phase accumulates in the filter and if not removed at certain intervals, it can lead to all sorts of complications, such as difficulties during removal, blocking or even disastrous damage of the filtering device. There were a number of attempts to control or monitor the loading of filters but results have been mediocre. This has to do with the fact that it is difficult to measure phase differences such as solid/liquid-phases inside the filtering device.

DrM now developed and patented a new device which does not attempt to monitor the phase but rather the forces acting on the filtering device. When overfilling occurs the filtering elements are displaced and such displacement is detected and a signal indicates that filtration shall be terminated.

The design incorporates distance sensors which are mounted above certain sections of the filtering device. Displacements of a few mm are enough to activate a signal.

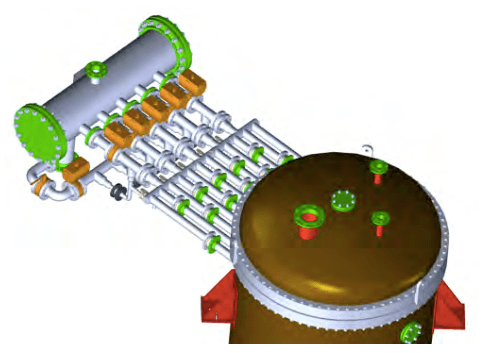

Specialized filtrate piping

DrM can supply headers which group multiple filtrate outlet nozzles into one single one, a manifold which collects the filtrate from the registers and can act as a buffer for the compressed gas required for blow-back, as well as a register by-pass with associated valves to be used when register-wide drying is implemented.

The process piping on filtrate side of the unit is an important but frequently underestimated part of the plant whose optimal choice is fundamental for a proper operation of the system.

A specific knowledge is needed for both the design and the fabrication, as these are depending on the actual process case: a significantly different approach is applied, for instance, if filter operates in dry or slurry discharge mode, if a need exists for a gas buffer for the blow-back operation, if the requested peak consumption for air/nitrogen can’t be guaranteed by the gas network (“register-wise drying” or “shock drying” are applied in that case), only to mention a few. One or more of the following elements can be part of the filtrate piping:

- the headers (in white with green flanges on one side in the drawing), which group 2 or 3 filtrate outlet nozzles into one single outlet.

- the manifold (in grey with green flat ends in the drawing), which collects the filtrate from the registers and can act as a buffer for the compress gas required for the blow-back

- the register by-pass with associated valves, used when register-wise drying is implemented.

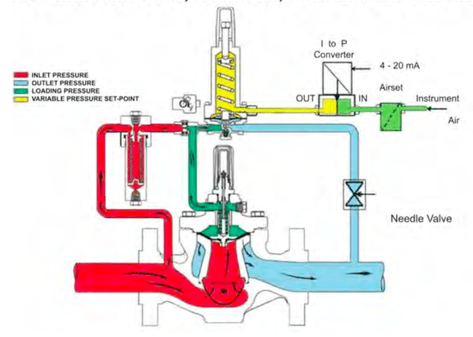

Pressure Reducing Valve

For proper operation, the FUNDABAC® candle Filter normally requires gas supplied at three pressure levels. In order to simplify the process and improve the functionality of the system, DrM recommends the Option of a single Pressure Regulating Valve (PRV) piloted by an I/P transducer. Compared with conventional solutions such as control valves controlled by a pressure transmitter, the PRV allows a much faster response and more accurate pressure regulation, preventing risks of cloth damages due to excessively high gas pressure or of inefficient cloth cleaning due to insufficient gas pressure.

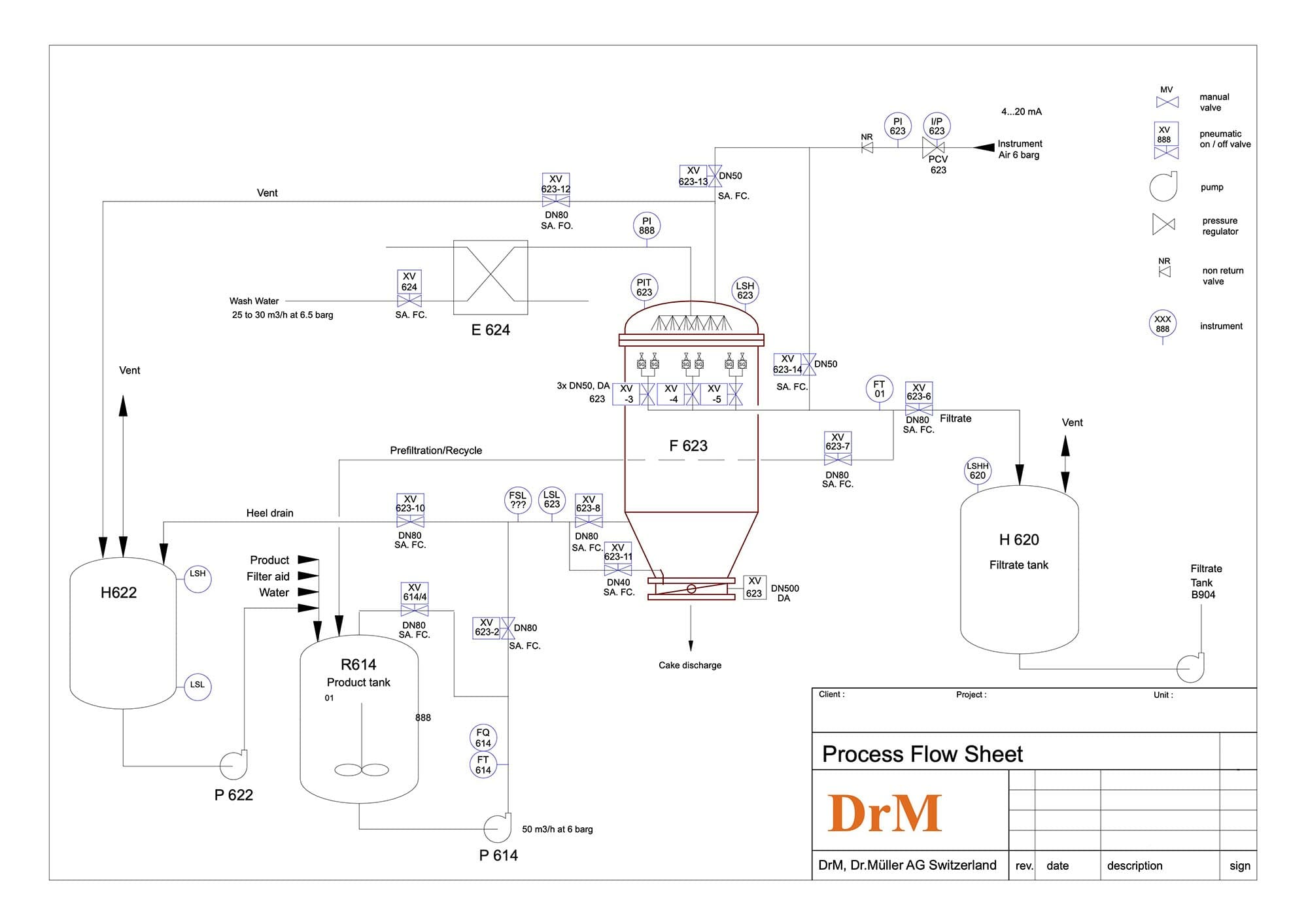

Process Engineering and Control System Packages

DrM can support the activities of very large plants as well as small ones with customized Process Engineering and Control System packages. These packages include:

-

- Process Flow Diagrams: A simple and immediate approach to all the important process and control information.

-

- Control Logic Diagram or Step-by-Step Sequence Chart: A matrix of steps and process phases that includes filter filling, cloth cleaning, as well as precoat/prefiltration, filtration, washing, draining, drying and discharge). This is intended to show all valves commands, instruments, loops and conditions, call operator alarms, pumps status, set points, timers, etc.

-

- Process Control Philosophy and Process Description: Narrative description of all phases, interlocks and alarms, safety conditions, set points and instruments ranges, etc.

Furthermore, DrM has developed a self-explanatory PLC software which does not require any programming knowhow. The user can control the process and modify the cycle configuration (add/remove process steps, modify timers and set points) from the HMI with no external assistance. A control panel with programmed PLC is the ideal filter add-on to avoid any process control issue.

Discharge Valve

Among the most critical components for the successful operation of a FUNDABAC® Candle Filter is a discharge valve that ensures both a problem-free cake discharge as well as a tight shut-off under pressure when closed. A wide range of disc and valve seat materials of construction is available. The candle element placement and the presence of the heel drain pipe are other factors that make both the selection and the installation of a discharge valve a critical step in a successful system design. Bottom discharge valves are typically required to be within the scope of DrM’s supply.

Spares

Please contact [email protected] for specific inquiries or general information related to spare parts. Our goal is to provide quick turnaround times for your spare parts orders. Please let us know when you have an urgent requirement and we will do everything we can to accommodate your needs.

- A wide range of Filter Options are available to optimize filter performance, operation efficiencies and flexibility.

- Options include skidding, specialized filtration piping, specialized pressure reducing and discharge valves, process engineering and control system packages, as well as spare parts.

- Spare parts are inventoried in both Houston and Switzerland. Switzlerland-stocked spares can be overnighted to meet customer delivery requirements.

DrM, Dr. Mueller AG

Alte Landstrasse 415

8708 Maennedorf

Switzerland

Phone: +41 44 921 2121

Fax: +41 44 921 2131

[email protected]