FUNDABAC® SU – Multi-Batch Filtration System For The Flavor & Fragrance Industry

Meeting the Product Processing Goals of Flavor & Fragrance Manufacturers:

Flavor and fragrance manufacturers demand a high level of product quality and processing safety. Flavors and fragrances must be filtered to achieve desired standards of clarity, color and stability. Filtration needs range from clarification to final polishing.

The FUNDABAC® SU filter provides producers of flavors and fragrances with process flexibility and allows them to meet stringent product quality and processing safety requirements. The FUNDABAC® SU filter is not only capable of capturing solid particulate matter, including microbial contaminants, in flavor and fragrance products, but can also reduce haze, absorb essential oil, as well as remove insoluble waxes/ lipids, unwanted water and color.

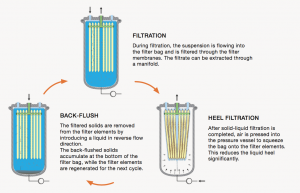

Operational Principle:

DrM’s new single-use filter type, FUNDABAC® SU, consists of large surface area filter elements, packed into a fully contained plastic enclosure. The increased surface area boosts the filtration efficiency and results in a higher throughput. The filter bag is installed in a pressure vessel during filtration.

This unique system design allows for single batch or multi-batch product processing.

For multi-batch operation the solids can be flushed back from the filter elements and accumulated on the bottom of the bag. When desired, materials such as cellulose fibers, activated carbon, diatomaceous earth, bleaching earth or magnesium silicate adsorbent media can be injected into the plastic bag enclosure with the goal of coating the filter elements in order to reduce, adsorb or remove the non-particulate undesirables previously mentioned.

Key Advantages:

- High product yield relative to filter media surface area

- No cross-contamination

- Virtually no liquid heel volume

- Fully enclosed environment

- No cleaning-in-place required

- No operator contact with liquids or solids, therefore safe operation

- Quick and easy disposable bag installation and replacement, minimal downtime

- Lab and pilot size models for trials and scalability

- Small footprint as a result of its compact design